The Honeycomb Panel Production Line plays a crucial role in the modern construction, transportation, and aerospace industries. As industries continue to demand stronger yet lighter materials, honeycomb panels have become increasingly popular due to their excellent strength-to-weight ratio. This article delves into the future of honeycomb panel production lines in China, exploring advancements in technology and the impact on production efficiency.

Honeycomb panels are made by bonding thin sheets of metal, fiberglass, or plastic to a core material that resembles a honeycomb structure. This design not only provides strength but also offers superior insulation, making honeycomb panels ideal for applications in various sectors. However, the production process can be complex and requires precise equipment to achieve the desired quality and performance.

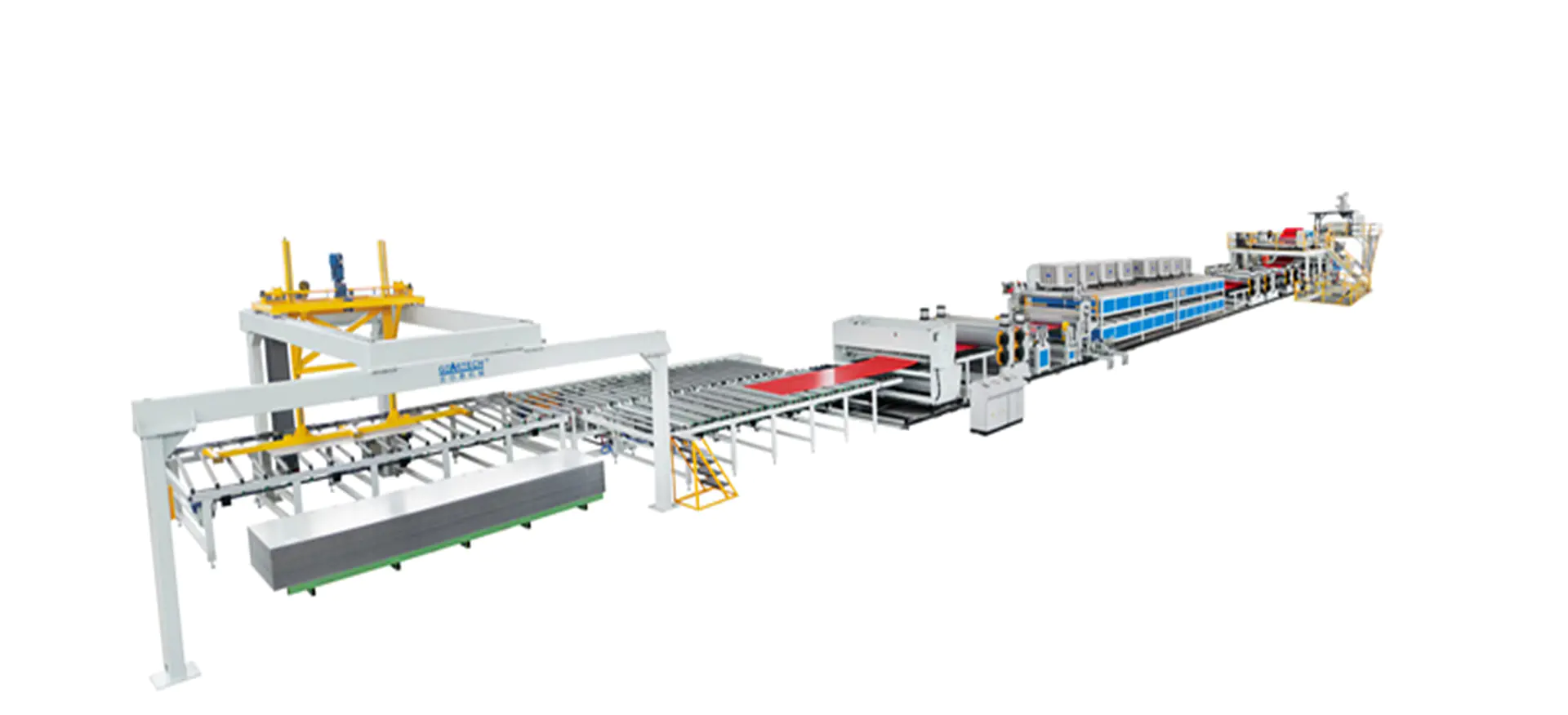

China, being a global manufacturing hub, is at the forefront of developing and improving honeycomb panel production lines. Innovations in automation, material handling, and digital control systems have drastically improved production efficiency. Modern production lines utilize advanced machinery that integrates automated systems for cutting, bonding, and curing, significantly reducing labor costs while ensuring high precision and consistency in the panels produced.

The introduction of robotics into honeycomb panel production lines has further enhanced efficiency. Robotic arms are capable of performing repetitive tasks such as handling raw materials, applying adhesives, and assembling panels. This not only reduces the risk of human error but also speeds up the entire production process. Additionally, the integration of artificial intelligence (AI) allows for real-time monitoring and adjustments to optimize production quality, ensuring that every panel meets the required standards.

Environmental sustainability is also a driving factor in the evolution of honeycomb panel production lines in China. Manufacturers are increasingly adopting eco-friendly materials, such as recyclable core materials and non-toxic adhesives. This focus on sustainability aligns with global efforts to reduce carbon footprints and environmental impact, further enhancing the reputation of Chinese manufacturers in the international market.

In conclusion, the honeycomb panel production line is evolving with the integration of advanced technologies such as automation, robotics, AI, and sustainable practices. As these innovations continue to improve production efficiency and reduce costs, China is set to maintain its leadership in this field, providing high-quality honeycomb panels for industries worldwide.

https://www.coating-line.com/product/acp-production-line.html

Application of Product and characteristics:

The final product ACP can be widely used in field of construction decoration such as curtain wall, interior and exterior wall of building,ceiling,column,storefront,billboard,exhibition rack,and auto etc.

1.High capacity and various thickness from 1mm to 8mm ;

2.The thickness range of Aluminum coil covers 0.018mm-0.5mm ;

3.Can use recycled PE ;

4.Stable technics and easy operation ;